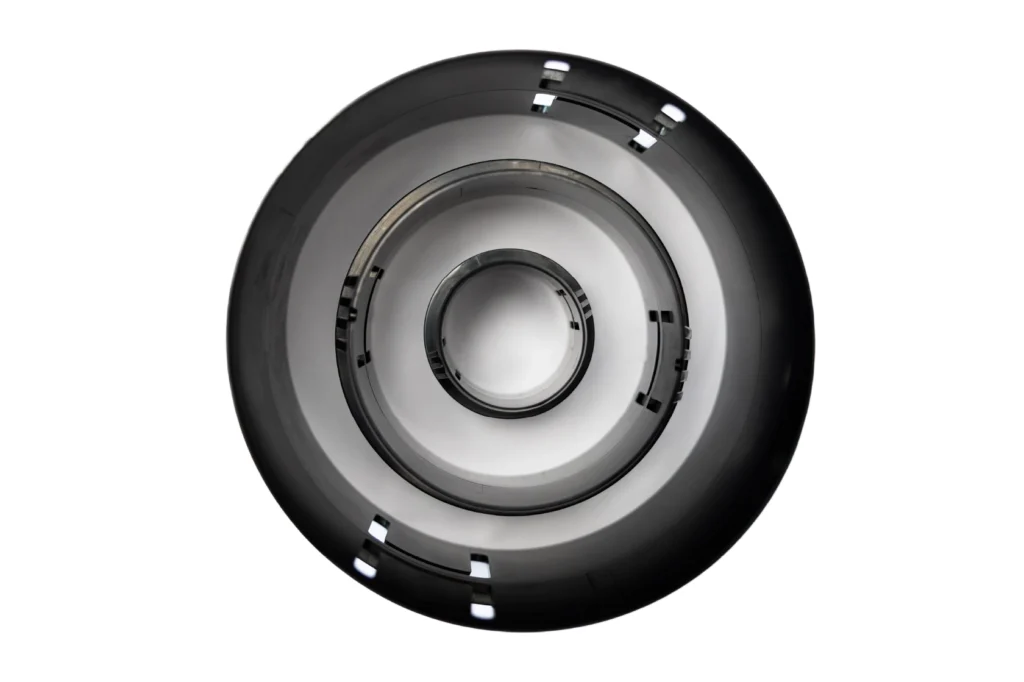

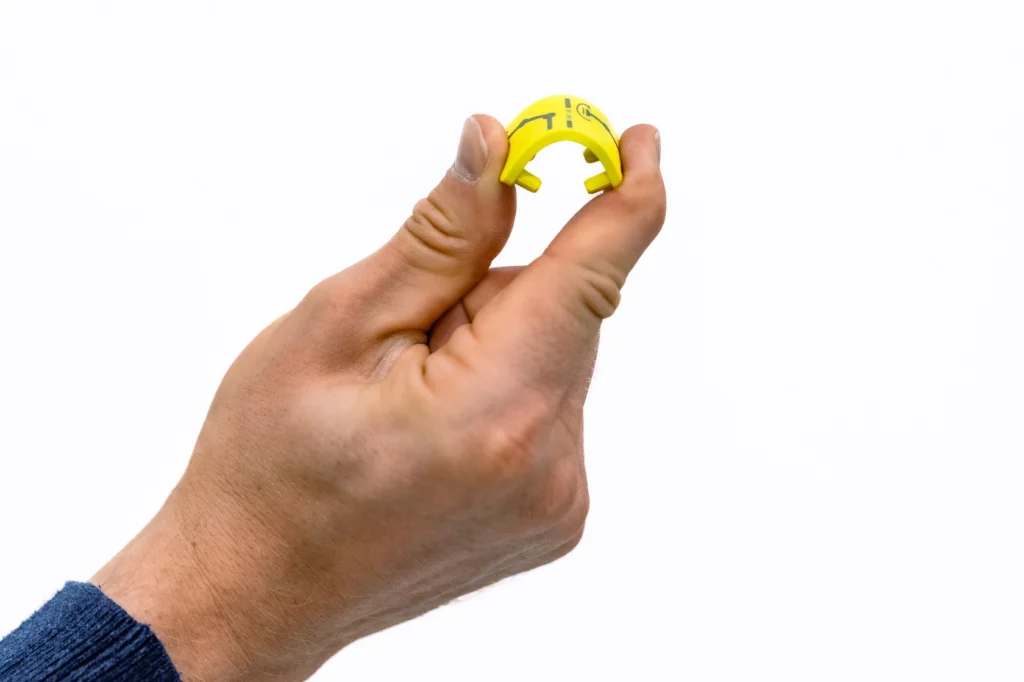

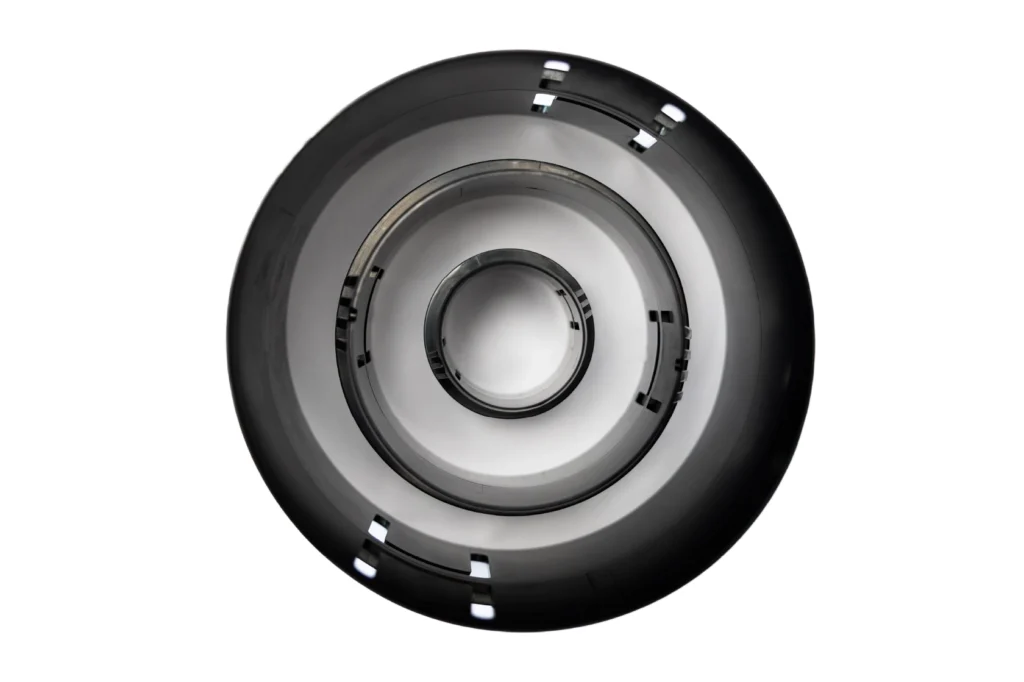

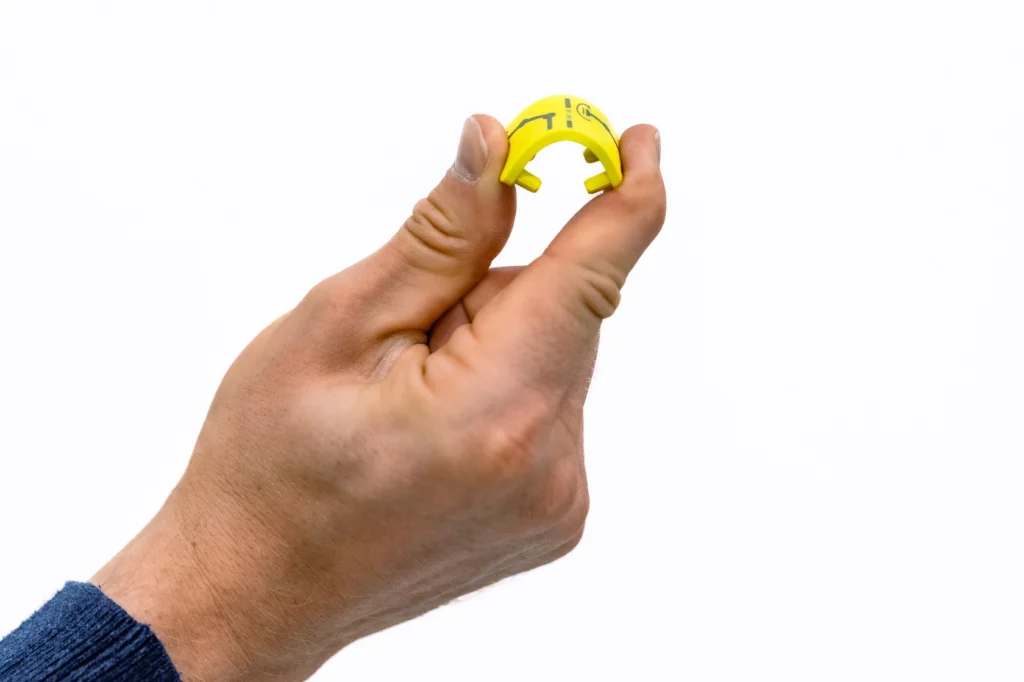

Injection moulding is one of the most common manufacturing methods for plastic products, and provides almost unlimited possibilities. We have been pioneering the field since 1954, when we bought our first injection moulder. Since then, we have designed, developed and produced thousands of different products for our customers and for our piping system KPS, which is used by global oil companies to safely transport fuel beneath forecourts in over 100 countries.

The injection moulding process involves melting plastic granules, injecting the liquid plastic into a mould and cooling it down. We have optimised the process, with key refinements relating to mould design, process control and the relevant pre and post-manufacturing process operations.

Today, our facility in Kungsör has 15 injection moulders in a variety of sizes, with a high level of automation.

KEY FEATURES:

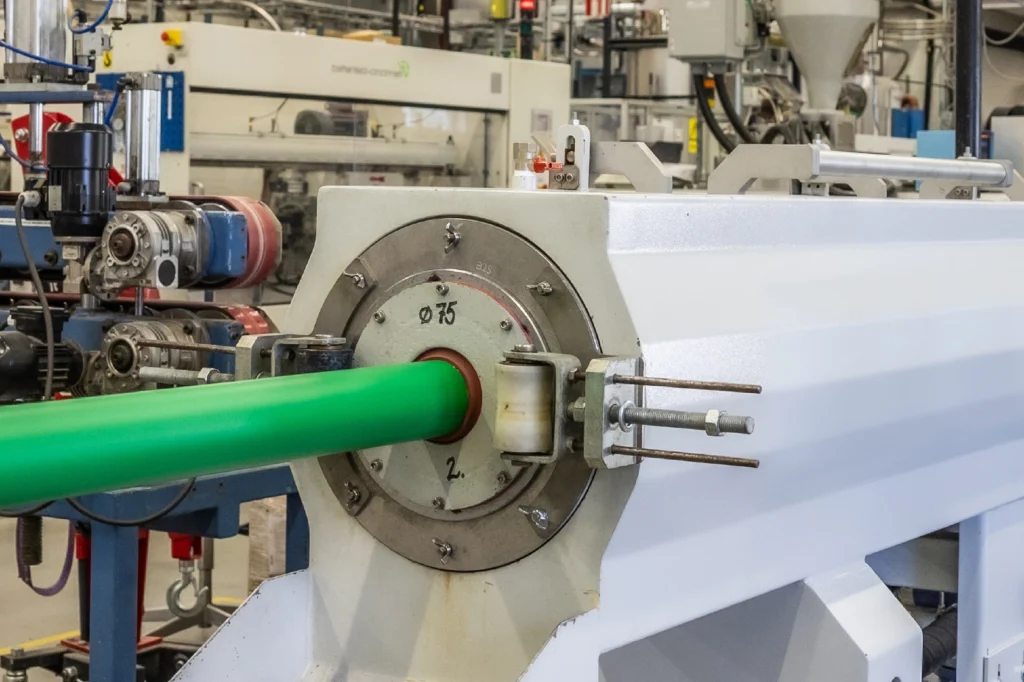

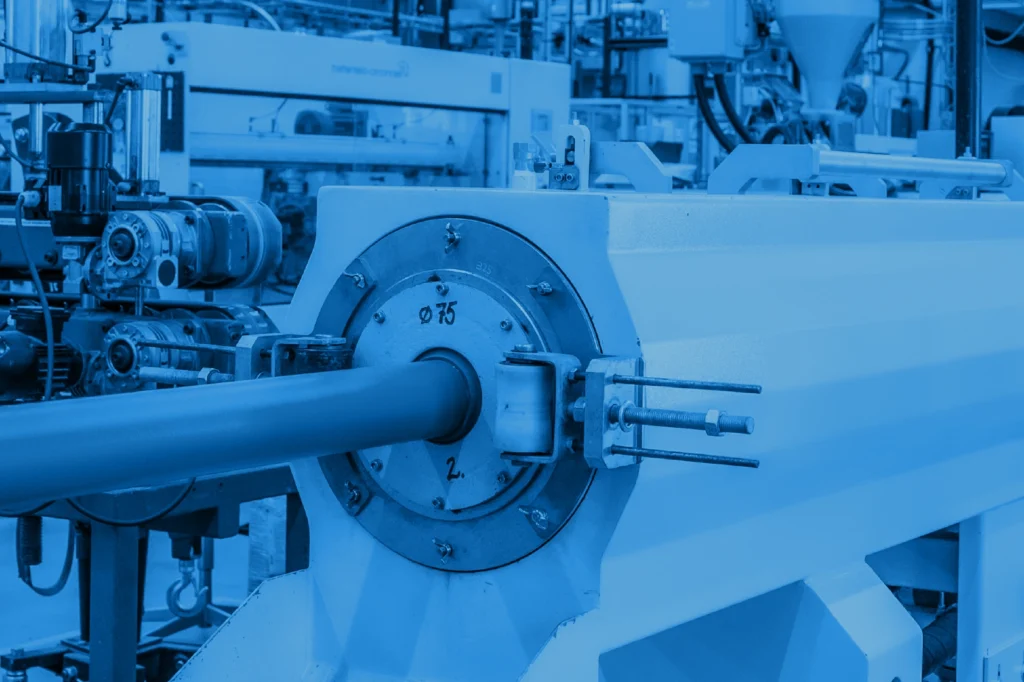

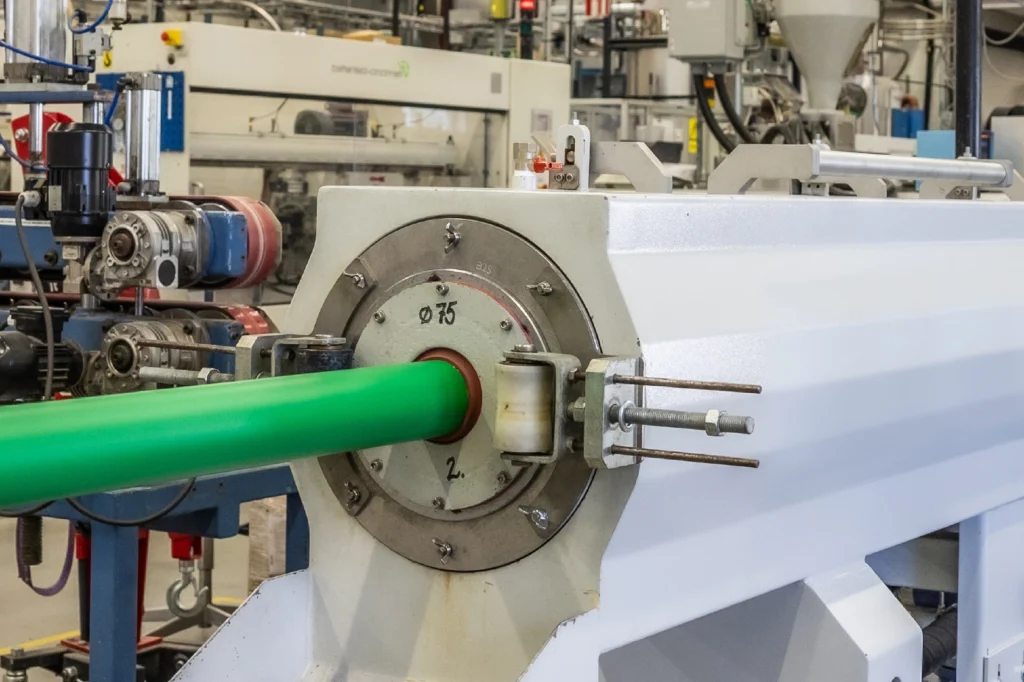

Extrusion is the manufacturing method for producing plastic products by the metre, also commonly known as continuous products.

As with injection moulding, plastic granules are melted, but in extrusion, the transport distance between melting and cooling is longer. An extrusion screw pushes the melted plastic through a nozzle, which includes a die of the desired cross-section/profile, shaping the plastic, which is then further defined in a calibrator, then passed through a cooling bath.

Our speciality lies in creating multiple layers inside profiles (up to 4). Each layer adds functionality; for example, our KPS piping system includes layers for electrical conductivity and a permeation barrier. We can also extrude multiple profiles inside each other (each with multiple layers), as evidenced by our double wall KPS piping system, which includes an inner and outer pipe for added security, and to enable leak monitoring.

KEY FEATURES:

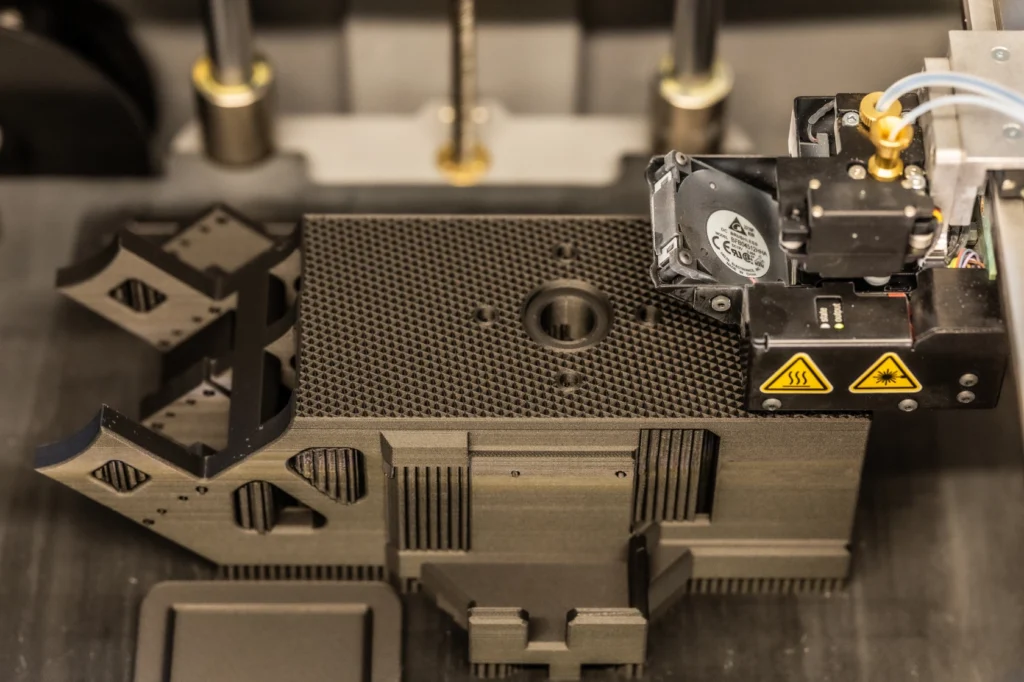

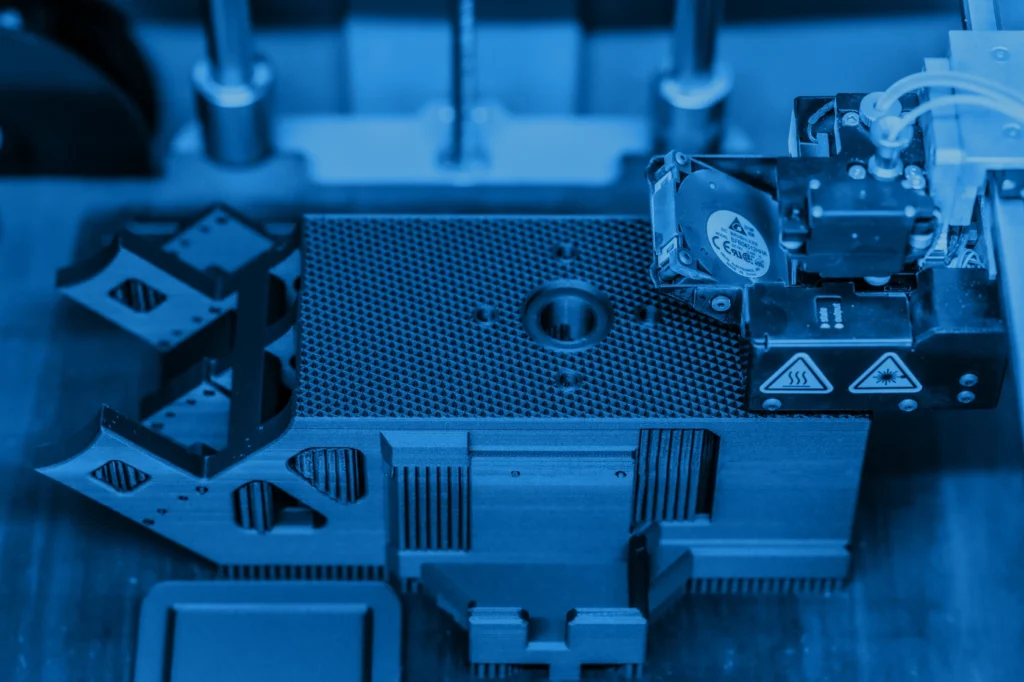

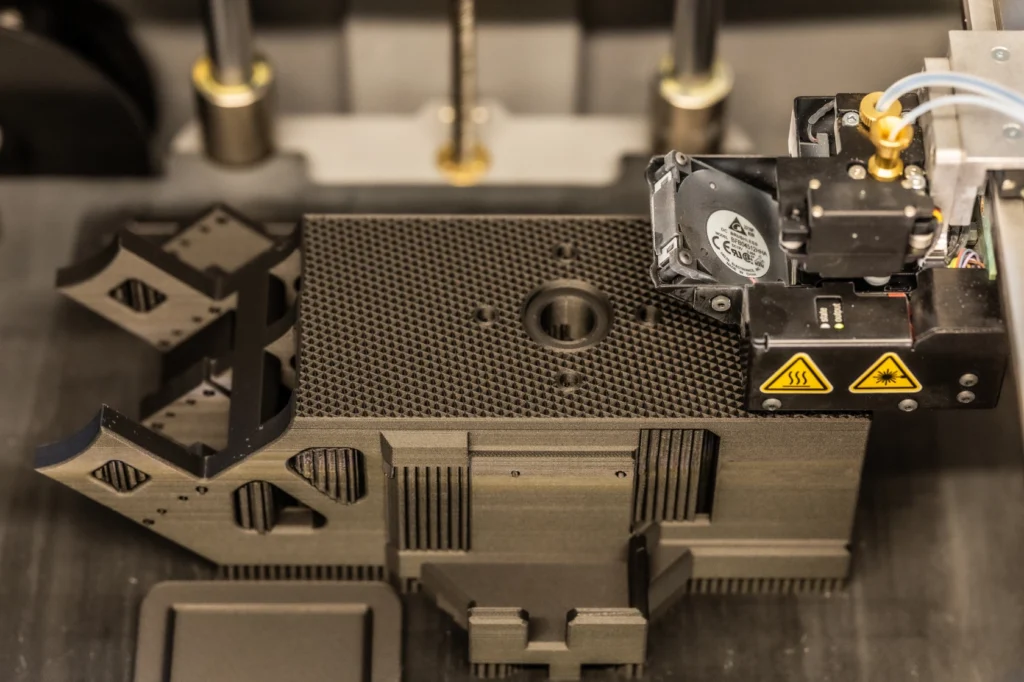

3D printing, also known as additive manufacturing of plastic components has grown and developed enormously in recent years.

While more costly for high-volume production (over 1,000/year) as compared to injection moulding, it is ideal for small volume production, complicated geometries and prototyping during product development.

In our 3D printers, we use threads of material that create the product droplet by droplet according to the input drawing.

We manufacture products up to the size of 330 mm (width) by 270 mm (depth) by 200 mm (height) with industrial accuracy and quality.

KEY FEATURES:

In our assembly department, we complete all the steps necessary to finalise a complete product. These include a range of manual and semi-automated operations: assembly, conditioning, butt-welding, cutting and drilling, sustainable laser marking and packing. If you’re interested in methods not mentioned here, please contact us here.

KEY FEATURES/methods:

For standard, budget-friendly plastic components. Lightweight, strong, resistant against chemicals and ductile at low temperatures.

Materials

PE – polyethylene (LDPE, MDPE, HDPE)

PP – polypropylene

PA – polyamide (Nylon)

For high-performance components with specific demands like dimensional stability, strength, transparency or electrical conductivity, there is a wide range of available materials.

Materials

PA6 GF30 – glass fibre reinforced polyamide

PC – polycarbonate

ABS – acrylonitrile butadiene styrene

PET – polyethylene terephtalate

PBT – polybutylene terephtalate

POM – polyoxymethylene

PS – polystyrene

PUR – polyurethane

For rubber applications, there are a number of highly elastic thermoplastics.

Materials

TPE – Thermoplastic elastomer

TPU – Thermoplastic polyurethane

For applications requiring specialist properties like extreme strength, high temperature resistance, high erosion resistance or super-low friction, we offer specialist materials.

Materials

PEEK – polyether ether ketone

PVDF – polyvinylidene fluoride

PEX – cross-linked polyethylene

For standard, budget-friendly plastic components. Lightweight, strong, resistant against chemicals and ductile at low temperatures.

Materials

PE – polyethylene (LDPE, MDPE, HDPE)

PP – polypropylene

PA – polyamide (Nylon)

For high-performance components with specific demands like dimensional stability, strength, transparency or electrical conductivity, there is a wide range of available materials.

Materials

PA6 GF30 – glass fibre reinforced polyamide

PC – polycarbonate

ABS – acrylonitrile butadiene styrene

PET – polyethylene terephtalate

PBT – polybutylene terephtalate

POM – polyoxymethylene

PS – polystyrene

PUR – polyurethane

For rubber applications, there are a number of highly elastic thermoplastics.

Materials

TPE – Thermoplastic elastomer

TPU – Thermoplastic polyurethane

For applications requiring specialist properties like extreme strength, high temperature resistance, high erosion resistance or super-low friction, we offer specialist materials.

Materials

PEEK – polyether ether ketone

PVDF – polyvinylidene fluoride

PEX – cross-linked polyethylene

For extruded products (extrusion grade materials).

Materials

PE – polyethylene (LDPE, MDPE, HDPE)

PP – polypropylene

Additional layers

PE – polyethylene

EVOH – ethylene vinyl alcohol

For 3D printing/additive manufacturing, the materials are tailor-made for and supported by the printer and printer manufacturer to deliver the best possible results.

Materials

PA based materials with different % of glass fibre reinforcement

TPE based materials for rubber-like properties

Through the years, we have produced items of many different materials, and we continue to explore new materials, including recycled plastics.

Materials

Please contact us if you’re interested in other materials.

For products which need additional non-plastic components to make complete products like inserts or fastening elements, we have a large network of trusted suppliers.

For extruded products (extrusion grade materials).

Materials

PE – polyethylene (LDPE, MDPE, HDPE)

PP – polypropylene

Additional layers

PE – polyethylene

EVOH – ethylene vinyl alcohol

For 3D printing/additive manufacturing, the materials are tailor-made for and supported by the printer and printer manufacturer to deliver the best possible results.

Materials

PA based materials with different % of glass fibre reinforcement

TPE based materials for rubber-like properties

Through the years, we have produced items of many different materials, and we continue to explore new materials, including recycled plastics.

Materials

Please contact us if you’re interested in other materials.

Injection moulding is one of the most common manufacturing methods for plastic products, and provides almost unlimited possibilities. We have been pioneering the field since 1954, when we bought our first injection moulder.

Since then, we have designed, developed and produced thousands of different products for our customers and for our piping system KPS, which is used by global oil companies to safely transport fuel beneath forecourts in over 100 countries.

The injection moulding process involves melting plastic granules, injecting the liquid plastic into a mould and cooling it down. We have optimised the process, with key refinements relating to mould design, process control and the relevant pre and post-manufacturing process operations.

Today, our facility in Kungsör has 15 injection moulders in a variety of sizes, with a high level of automation.

KEY FEATURES:

As with injection moulding, plastic granules are melted, but in extrusion, the transport distance between melting and cooling is longer. An extrusion screw pushes the melted plastic through a nozzle, which includes a die of the desired cross-section/profile, shaping the plastic, which is then further defined in a calibrator, then passed through a cooling bath.

Our speciality lies in creating multiple layers inside profiles (up to 4). Each layer adds functionality; for example, our KPS piping system includes layers for electrical conductivity and a permeation barrier. We can also extrude multiple profiles inside each other (each with multiple layers), as evidenced by our double wall KPS piping system, which includes an inner and outer pipe for added security, and to enable leak monitoring.

KEY FEATURES:

In our 3D printers, we use threads of material that create the product droplet by droplet according to the input drawing.

We manufacture products up to the size of 330 mm (width) by 270 mm (depth) by 200 mm (height) with industrial accuracy and quality.

KEY FEATURES:

These include a range of manual and semi-automated operations: assembly, conditioning, butt-welding, cutting and drilling. sustainable laser marking and packing. If you’re interested in methods not mentioned here, please contact us here.

KEY FEATURES/methods:

For standard, budget-friendly plastic components. Lightweight, strong, resistant against chemicals and ductile at low temperatures.

Materials

PE – polyethylene (LDPE, MDPE, HDPE)

PP – polypropylene

PA – polyamide (Nylon)

For high-performance components with specific demands like dimensional stability, strength, transparency or electrical conductivity, there is a wide range of available materials.

Materials

PA6 GF30 – glass fibre reinforced polyamide

PC – polycarbonate

ABS – acrylonitrile butadiene styrene

PET – polyethylene terephtalate

PBT – polybutylene terephtalate

POM – polyoxymethylene

PS – polystyrene

PUR – polyurethane

For rubber applications, there are a number of highly elastic thermoplastics.

Materials

TPE – Thermoplastic elastomer

TPU – Thermoplastic polyurethane

For applications requiring specialist properties like extreme strength, high temperature resistance, high erosion resistance or super-low friction, we offer specialist materials.

Materials

PEEK – polyether ether ketone

PVDF – polyvinylidene fluoride

PEX – cross-linked polyethylene

For extruded products (extrusion grade materials).

Materials

PE – polyethylene (LDPE, MDPE, HDPE)

PP – polypropylene

Additional layers

PE – polyethylene

EVOH – ethylene vinyl alcohol

For 3D printing/additive manufacturing, the materials are tailor-made for and supported by the printer and printer manufacturer to deliver the best possible results.

Materials

PA based materials with different % of glass fibre reinforcement

TPE based materials for rubber-like properties

Through the years, we have produced items of many different materials, and we continue to explore new materials, including recycled plastics.

Materials

Please contact us if you’re interested in other materials.

For products which need additional non-plastic components to make complete products like inserts or fastening elements, we have a large network of trusted suppliers.

From initial contact through to scoping, production, delivery, and post-delivery support – talk to Mark.